Ladtech

In today’s increasingly competitive market, it’s not enough to offer top-notch products at affordable prices. Businesses need to gauge fluctuations in demand, prepare for spikes, and optimize logistical capabilities accordingly.

The case study below illustrates how Spartek helped a client meet this challenge.

The Challenge

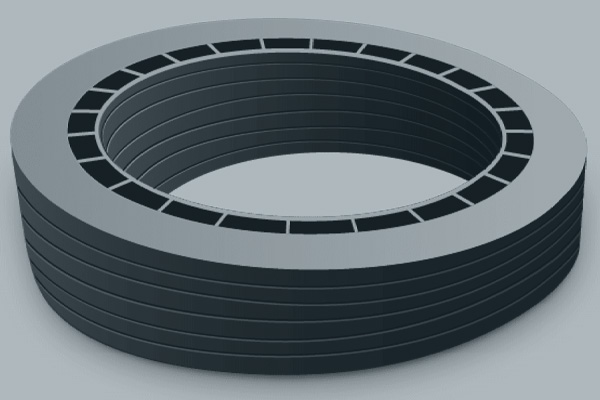

One of our clients, Ladtech, Inc., a manhole adjusting ring manufacturer, came to us in need of injection molding services. Sometimes referred to as adjusting rings or grade rings, manhole adjusting rings are crucial components in many rural and urban resurfacing projects. These components eliminate the need to raise or replace existing manhole frames during resurfacing, allowing existing manholes to sit flush with newly repaired roads while saving on contract labor, expenses, and work time.

The client required injection molded manhole rings in various sizes, and needed a high-volume order completed every year.

But because these rings are used in construction projects, demand typically dips during the offseason. So, to cut overhead, Ladtech was also looking to streamline its entire production cycle, from production scheduling, manufacturing, and warehousing to inventory management and shipping. They wanted to plan for the low-demand season during the year ahead and warehouse the units accordingly.

The Solution

We injection molded the needed parts for Ladtech, providing them with rings in the following sizes:

- 24 inches and 27 inches — 1 ¼ inches, 1 ½ inches, 2 inches, 4 inches flat, and 1 ½ inches slope

- 30 inches — 1 ½ inches, 2 ¼ inches flat, and 2 ¼ inches slope

- 32 inches and 34 inches — 2 inches, 3 inches flat, and 2 ¼ inches slope

- 24 inches x 36 inches catch basin — 1 ½ inches, 2 inches, 2 ¾ inches flat, and 1 ½ slope

- 24 inches x 24 inches catch basin — 1 ½ inches, 2 inches, 2 ¾ inches flat, and 2 ¾ inches slope

All units are made of post-consumer, mixed-color polyethylene flakes.

To address their unique inventory and coordination needs, we created a custom program that would allow the Ladtech team to keep a finger on the pulse of their production cycles while tasking us with the details of optimizing warehousing, inventory management, shipping, and production coordination.

We created a full-service plan that took into account every step of the production process, allowing for appropriately scaled inventory and much more efficient, streamlined processes.

The Result

Ladtech was thrilled with the results, and was particularly impressed with our customer service capabilities. We now produce and ship 200,000+ of these parts every year.

Ladtech is now able to plan for dips in demand during the offseason and stock their product accordingly, saving on unnecessary expenses.

Learn More

Spartek is proud to offer full-service production coordination capabilities for clients across a range of industries.

To learn more about our past work or discuss how we can help with your unique application, contact us today.